Food borne diseases & global scenario:

Up to 30% of the population in industrialized countries may be affected by food-borne illness each year and the problems are likely to be even more serious in developing countries. The global incidence of food-borne disease is difficult to estimate, but in 2005 it was estimated that 2.2 million people, including 1.8 million children died from diarrheal diseases. Microbiological hazards represent 93% of the incidents of food-borne illness and are the major problems not only in developing countries but also in developed countries.

Salmonella is a leading cause of foodborne disease in humans worldwide and is a significant cause of morbidity and even mortality and consequently high economic losses (Foley and Lynne, 2008). Every year almost 1 in 10 people fall ill and 33 million of healthy life years are lost. CDC estimates Salmonella causes about 1.2 million illnesses, 23,000 hospitalizations, and 450 deaths in the United States every year. Hoffmann et al (2013). estimated the total economic burden of foodborne Salmonella in the United States to be $3.7 billion in 2013. According to David Byrne, EU Commissioner for Health and Consumer Protection, the costs of food-borne Salmonella alone are estimated to reach up to € 2.8 billion annually in EU countries altogether (European Commission, 2003).

Although many foods contain Salmonella, raw meats, poultry, eggs, milk, and dairy products are often implicated as sources of infection (Jones, 2011). For this reason, consumers are increasingly concerned about Salmonella contaminations in their food. Barring Salmonella gallinarum (S. gallinarum) and Salmonella pullorum (S. pullorum) there are several serotypes of Salmonella which infect both humans and poultry and can produce infections in consumers by entering through the food chain.

There are many sources of Salmonella contamination in animals, including feed and feed ingredients such as seeds and cereal grains (Sanchez et al., 2002). Managing the contamination through feed is paramount to reduce the incidences in animals and subsequently in humans

Prevalence of Salmonella contamination in feed and feed ingredients in India:

Apart from vertical transmission, one of the potential routes of entry of Salmonella infection in animal health is feed and feed ingredients. It is obvious to get other Enterobacteriaceae like E. coli along with Salmonella in feed and ingredients. Salmonella contamination has been associated with an elevated indicator organism such as Enterobacteriaceae counts (Jones, 2011). Enterobacteriaceae counts higher than 104 cfu/g in unprocessed feeds and higher than 102 cfu/g in processed feeds may be an indicator of Salmonella presence (Jones and Richardson, 2004).

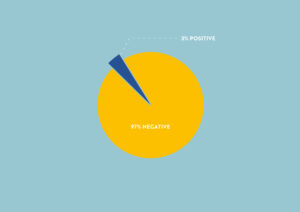

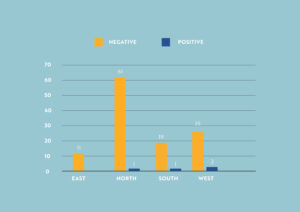

It was found through a feed mill survey from April 2020 to March 2021 in India, around 3% of tested samples had Salmonella contamination. Few of the samples from North, South and West India were Salmonella positive. Data shows the prevalence of positive samples in the post monsoon period. This is the period mostly when feed hygiene is taken less seriously. Moisture optimization plus feed hygiene products not used considering optimum percentage of moisture in feed may be probable reason of inferior hygiene in practical sense.

Strategies to manage Salmonella contamination & transmission through feed:

Feed has been referred to as a “major source of transmission” of Salmonella into commercial farms. It is proven in several studies that when feed quality management systems based on HACCP (Hazard Analysis and Critical Control Point), GMP (Good Manufacturing Practice) and Good Hygiene Practices, were implemented across all feed mills in the survey, incidences of Salmonella outbreak in poultry farms are considerably reduced. Good manufacturing practices including operational procedures are aimed at producing feed that is safe and of consistent quality. A key element of feed safety is to produce the feed that is microbiologically safe and is produced in a premise where the feed hygiene management system is in place. Salmonella control program is to produce feed that is free of all Salmonellae. Hazard analysis and critical control point determination is needed to systematically identify, analyse and control. Four essential elements of a Salmonella control programme have been defined as;

1. Stringent policies of raw material purchase

2. Strict supply chain

3. Manufacturing facility sanitation and cleaning

4. Good manufacturing practices

1.Stringent policies of raw material purchase:

It is well known that Salmonellae can enter the feed milling system from feed ingredients and with insects being vehicles for the spread of bacteria. To some extent conditioning during pellet feed manufacturing, Salmonella is killed. Whereas in mash feed chances of transmission through feed is very common. Feed ingredient supplier management systems including monitoring of ingredients for Total Enterobacteriaceae Counts (TEC) and Salmonella count are required.

Supplier’s evaluation in terms of inspection of storage area, checking and inspection of raw materials, signing off the approved ingredient specification, even the inspection of the vehicles for hygiene and disinfection are part of the feed ingredient supplier management system. Moreover the process of supply should be certified as per GMP and HACCP system

2. Strict supply chain

Throughout the supply chain stringent inspection and testing are of paramount importance. At the receiving point, verify the documents and compare with approved quality management parameters. A programme of aseptic sampling of feed ingredients and from vehicles is required to determine where microbial contamination and multiplication are occurring so that targeted corrective and preventative actions can be implemented. Microbiological quality especially Total Enterobacteriaceae Counts (TEC) and Salmonella counts are important. Additionally, delivery truck monitoring and hygiene are also needed. A thorough rodent and wild bird control programme is required to exclude this source of contamination of feed ingredients. Additionally, there should be in built quality check points for chemical quality and nutritional values.

3. Manufacturing facility sanitation and cleaning

This step is very important when feed is predominantly in mash form as there is no heat kill step. This requires comprehensive and effective mill hygiene procedures to keep each point along the milling process dry and clean with minimal dust accumulation.

Inside and outside of the factory shed, there should be a good water drainage facility. There should be no water logging and roofs, ceilings and walls should not allow water ingression. Maintenance of mill cleanliness must be a part of the mill’s GMP programme. Whilst regular cleaning procedures should be scheduled, physical cleaning should be a normal component of daily work functions, e.g. feed or feed ingredient spills should be cleaned up immediately to promote a good ‘cleaning culture’.

Dust proved to be the most important source for contamination of Salmonella and Enterobacteriaceae (Haggblom, 1994; Jones and Richardson, 2004). Therefore, it is very important to control dust in feed mills from the very beginning of the feed production, i.e. from the unloading process where the largest quantity of dust is produced (Morita et al., 2006). Grinders, mixers, elevator legs, conveyors, pellet scalpers are additional points of dust formation that must be controlled within the feed mills (McDaniel, 2005). Proper air circulation system, dust controlling cyclone, equipment cleaning and hygiene audit are to be the regular practice in feed plants.

Manufacturing waste, stored unused fat and scrapped raw materials in manufacturing plants are the breeding ground of bacteria and fungi. There is a need to assess the potential risk and are to be disposed properly. Overall ventilation and regular pest control are to be carried out. Pests like mealworms are the potential source of transmission of Salmonella infections

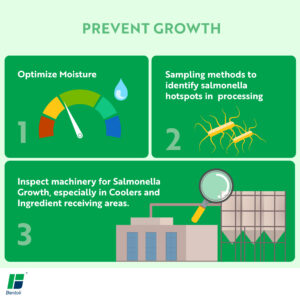

4. Moisture control and feed sanitation:

In the final feed, moisture should not be less or more than 11.5 to 12%. This is the optimum moisture percentage for better nutritional value and hygienic feed manufacturing. Higher moisture content invites growth of microbes and subsequently quality is deteriorated. Low moisture content may cause shrinkage of feed and factory yield and subsequently performance of the animals are impacted. Moisture optimization is now an established concept in feed manufacturing. Along with moisture control, using organic acid blends in feed can improve the feed hygiene ensuring check on transmission of pathogens like Salmonella spp and other enterobacteriaceae. Moreover, entry of Salmonella in the food chain could be checked resulting into production of safe food by improving feed hygiene.

Conclusion:

Food borne disease could be prevented by implementation of strict good manufacturing practice. As per FAMI-QS code implementation and managing feed safety management system is quintessential to reduce transmission of diseases in livestock and subsequently incidences of food borne disease in human beings.

Reference :

1. Tomicic, Z., Cabarkapa, I., Colovic, R., Duragic, O., Tomicic, R. ( 2019). Salmonella in the feed industry: Problems and potential solutions. Journal of Agronomy, Technology and Engineering Management, Vol. 2(1): 130-137 2. Foley, S.L., Lynne, A.M. (2008). Food animal-associated Salmonella challenges: pathogenicity and antimicrobial resistance. Journal of animal science, 2008 Apr;86(14 Suppl):E173-87